|

<< Click to picture of restored watch >>

|

| Old Seamaster |

The Seamaster series is the most historical in the OMEGA watches. This model was developed in 1950s, it was the golden age of the mechanical watch. A water resitant case was formed one piece part. A movement is great automatic caliber 562.

Now watching this watch closely, the case, the glass and the bracelet had been scratched and stained for several decades.

[NOTICE!]】

I did it as hobby and did not have high skill as same as the watchmaker.

Please ask them if you want to restore your vintage watches.

OMEGA Seamaster(made in switzerland)/SS case/34mmx10.3mm/Automatic cal.562/24 jewels/18,000bph

- Hard to winding

- Sometimes stopped. Unstable running

- Very wounded glass, case, bracelet

The case is one-piece structure. It does not have a caseback. At first, pull the crown by a pliers and remove the bezel. Releasing the lock which fixes the movement inside the case, the movement with the dial can be taken out.

|

|

|

| One piece case | Remove the crown | Release the lock |

The dial and the movement are nice condition only a water resitant case by OMEGA.

Caliber 562 has thick bridges and a swan neck regulator for high precision.

|

|

| Round dial with Applied bar indexs | Cal.562 24 jewels Automatic |

Glass, Bezel, Case, Dial, Movement

|

The screw is too tight and the tip of the screwdriver is damaged. I sharpened the driver tip to fit the slot of the screwtop and try several times.

|

|

|

| Damaged driver tip | Main plate | Automatic winding parts |

The disassembly step is as same as "Re-production of OMEGA Consteration". Please referthat explanation page.

|

| Caliber 562 was disassembled |

Now, it is ready to clean the parts with benzine. I use an ultrasonic cleaner

for the jewelry and eyeglasses.

After the clean, they should be dried with the microfiber cloth and blown

dust off.

The congealed grease is stuck to the mainspring and the keyless works.

So, they should be scrubed in benzine.

Really, It was too dirty to wind the spring. The oil congealed.

|

|

|

| Dirty mainspring | Clean up | Ultrasonic cleaner |

Coil and install the main spring into the barrel by hands. Place some of the oil on two or three places on the coil and barrel floor, and rub the remainder on some surface of the inner coils.

|

|

|

| installing mainspring | coiled mainspring | set the barrel |

Assemble the wheel train, the keyless works(winding mechanism) and the calender disk. Place the automatic winding bridge.

|

|

|

| Wheel train | Calendar mechanism | Automatic winding bridge |

Beautiful caliber 562.

|

| Assemby finished |

In the test running, the balance stopped shortly. I observed that the click did not engage the ratchet wheel and then it cannot wind up the barrel.

|

|

|

| not engaged click | error click spring(right) |

The click spring is not functioning properly because it contacts the wall of the click space.

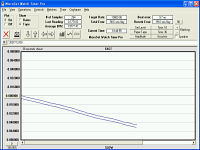

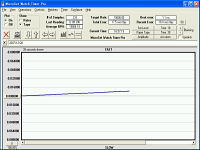

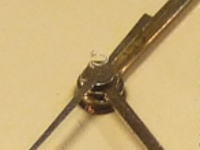

I use Microset Watch Time. It is veryt usable to check the rate on my PC screen.

|

|

|

| Befor | After | Microset |

My adjustment got following result,

| Position | Before | After | ||

| Daily rate | Beat error | Daily rate | Beat error | |

| Dial down | -98.8sec/day | 9.7ms | +7.5sec/day | 1.1ms |

| 6 o'clock up | -194.4sec/day | 11.4ms | +5.2sec/day | 0.6ms |

| 3 o'clock down | -110.2sec/day | 10.2ms | +1.2sec/day | 0.2ms |

Polish all hands and press them.

|

|

|

| stained hands | polished hands | hand press |

Attach the hour hand and the minute hand at 12 o'clock position.

There is clearance between hour and minute hand and the dial surface.

|

Rub off the rust and polish the case closely. And set the movement inside the case and lock it.

|

|

|

Put the OMEGA genuine palstic glass and cover it by the bezel.

|

|

|

| OMEGA genuine crystal | Transparent OMEGA emblem |

|

Attach the Bracelet cleaned by the ultrasonic cleaner.

It seems to be quite another watch now !

Winding is softy, the accurary is recovered. I am surprised the performance

of the caliber 562 which was manufactured before 60 years.

|

|